Automation, monitoring, and reports

Executional Excellence

Real-Time Monitoring

Clean Chemistry has prioritized engineering processes and combined them with sensor and automation packages to provide new levels of water treatment control and management. A system of inline sensors and cloud-based analytics promotes real-time monitoring, automatic treatment adjustments and quality control.

Clean Chemistry provides both standard and customizable performance monitoring and data collection packages to customers across many industries. On a typical job, these include online dashboard access that allows real-time monitoring of dose and Oxidation Reduction Potential (ORP). Job summary reports provide a complete overview of the project, including barrels treated and average key performance indicators (KPI).

Data Driven Processes

Clean Chemistry’s treatment processes and services are data-driven for quality and transparency. Data from treatment systems and field measurements are collected for analysis, reporting and archiving. Dashboards are used for internal management of operations and for external customer visibility to monitor project operation and status.

Daily Reporting

Automated reporting is available to provide a record of key performance parameters during operations. Whether using standard reporting practices or specific customer requests, Clean Chemistry provides daily reporting in addition to the online dashboard. Reports are sent automatically via email to all specified recipients.

Learn More:

Flexible Deployment Options

PeroxyMAX can be safely generated on-demand, near the point of application, and injected into the water stream where it is most needed: at the wellsite, at a pulp mill bleaching plant or on a food processing production line. In these applications, other oxidants are more challenging to use due to safety, odor, corrosion or chemical compatibility limitations.ᅠ

The Smart Chemical

Treatment Platform

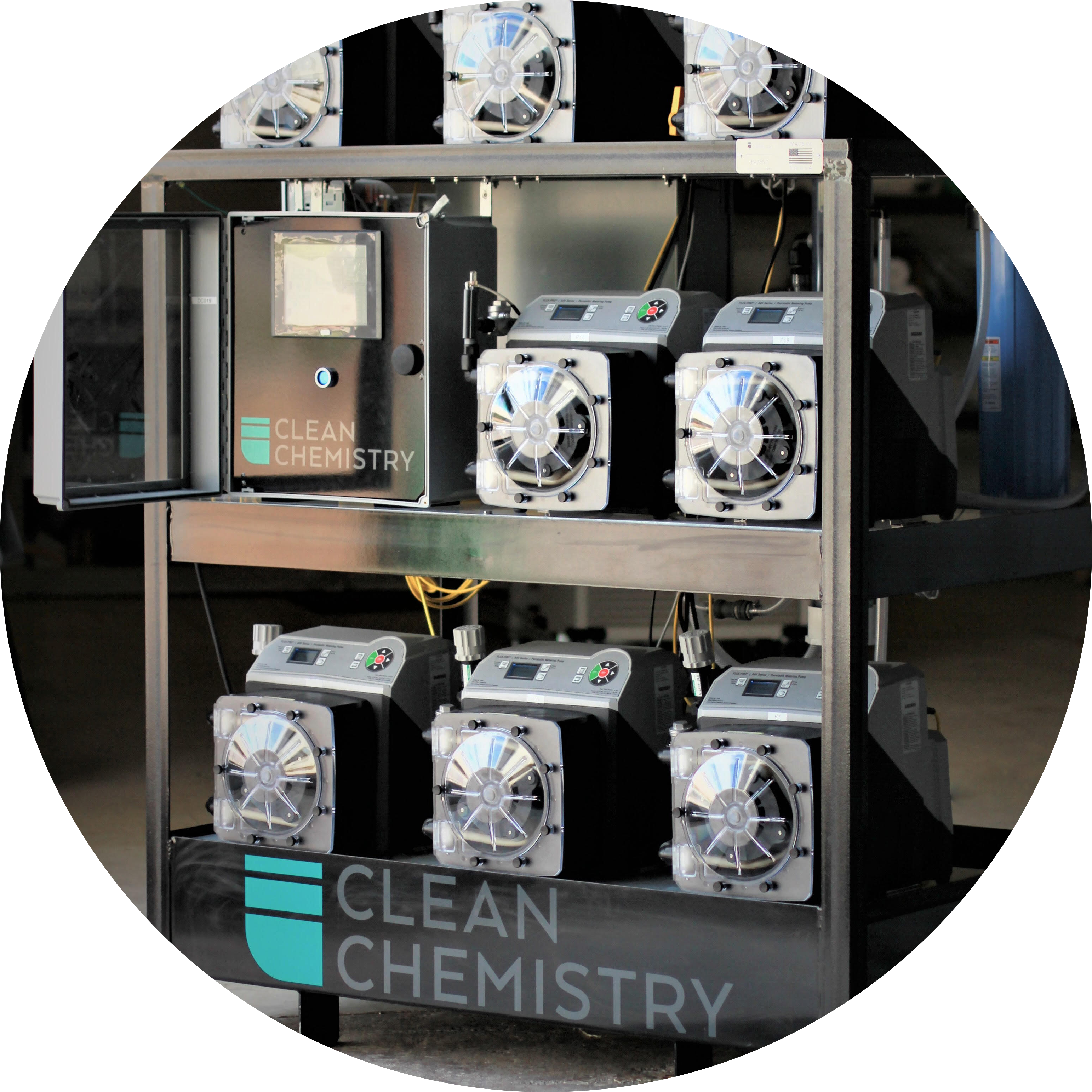

This small-footprint platform requires less power than a household dishwasher. A standard 3 ft by 4 ft sized system can produce 400 to 2000 pounds of PeroxyMAX a day. Systems can be scaled up or down to meet applications requirements and space constraints.

The PeroxyMAX™ Oxidation

Technology Trailer

Utilizes smart technology, enhanced automation, data driven quality control and adaptable chemical dosing for improved onsite operations. Quick setup, fast deployment and full cloud-backed connectivity allow PeroxyMAX technology to be deployed to any application location.ᅠ

Get Started with Clean Chemistry

"*" indicates required fields