For years, peracetic acid (PAA) has been the go-to oxidizer for water treatment. However, safety and economic concerns have led some industries to look for alternatives. The American Industrial Hygiene Association (AIHA) The Synergist blog lists some of the risks associated with using PAA in industrial or manufacturing environments.

In concentrated form, short-term exposure can cause irritation to the eyes, skin and respiratory tract. More acute exposure may lead to coughing, labored breathing, and shortness of breath; skin redness, pain, and blisters; and severe deep eye burns.

Other major concerns include possible fire and explosion dangers and reactivity issues, with improper storage and handling, since peracetic acid decomposes rapidly at higher temperatures in sunlight and reacts violently with soft metals such as brass, copper, iron, and zinc.

This does not take into account the cost of PAA or its high corrosion profile, which can lead to expensive equipment repair and replacement over time.

Clean Chemistry can provide an economical, environmentally-friendly alternative to recycle or safely dispose of water used in many industries. PeroxyMAX™, Clean Chemistry’s proprietary, foundational oxidant technology, is currently being utilized in full-cycle water treatment solutions for energy, pulp and paper, and cooling towers with expansion into food and beverage and other industrial water treatment applications. The technology was developed as an inherently safer, economic and environmentally more sustainable alternative to traditional oxidants and microbial control agents that provides superior performance in demanding industrial water process settings.

Efficient use of biocides for constantly changing water conditions over time and across different industries is a critical reliability and cost management challenge. A recent study has shown that more than five times the amount of peracetic acid (PAA) is needed to achieve the same microbial control performance of PeroxyMAX. The greater performance of PeroxyMAX reduces cost and increases reliability of water treatment.

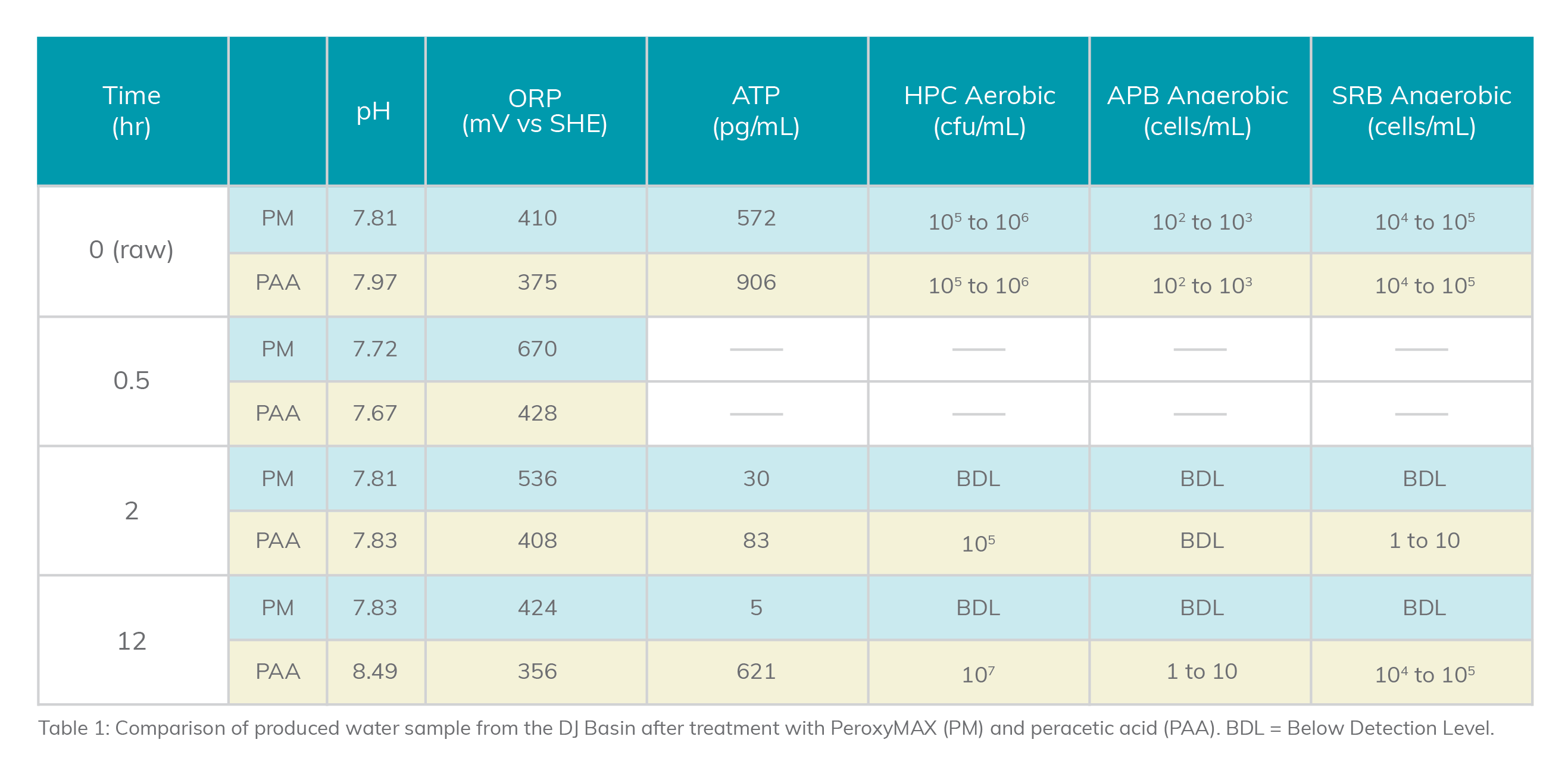

PeroxyMAX provided effective bacteria control within two hours while providing an elevated ORP (≥670 mV vs SHE) for at least 30 minutes. Bacteria cell counts in culture tests were reduced to below detection level (BDL) at two hours and 12 hours after treatment. Measured ATP concentration continued to decrease over 12 hours; presumably as non-viable cells continued to die off.

PAA treatment reduced ATP and the culturable anaerobic bacteria counts two hours after treatment but did not provide an ORP response significantly greater than dissolved oxygen. Almost complete recovery of bacteria activity was observed 12 hours after treatment indicating that the PAA dose was sub-lethal, while there was no microbial rebound found in the water treated with PeroxyMAX. In fact, culturable populations increased by two to three orders of magnitude in 10 hours (much greater than expected for regrowth) demonstrating that bacteria were temporarily inhibited by PAA.

Treating the produced water with 50 mg/L of PAA did reduce bacteria nearly completely. However, 1 to 10 cells/mL of SRBs survived overnight even at this level of treatment. Therefore, for this produced water, greater than five times more PAA was needed for complete bacteria control.

In addition to the enhanced performance of PeroxyMAX, there are safety, compatibility and automation advantages to the chemistry. Generated on site, in a low-pressure system from three stable liquid feedstocks, PeroxyMAX is an inherently safer oxidant technology. The elevated ORP response for PeroxyMAX can be correlated with performance and used for real-time process monitoring and control, especially important for changing water quality and oxidant demand. Best practices for successfully using PeroxyMAX include periodically verifying correlations between ORP and microbial control results as well as proper design of the treatment process. PeroxyMAX is compatible with equipment and other chemistries, as well. Less corrosive than peracetic acid and other, traditional oxidant chemistries, PeroxyMAX targets contaminants, not equipment, avoiding damage to equipment and other materials that come in contact with treated water. Treatment strategies with PeroxyMAX as the main oxidant also have good compatibility with other common chemicals for water treatment.

Clean Chemistry’s treatment technology provides effective microbial control, recycles the water used in many operations—reducing fresh water requirements, and protects the environment by removing contaminants so “used” water can be safely reused or disposed. All of this leads to a lower total cost of operations for the customer. Our unique formulations are applicable to any industry where safe, reliable and sustainable water use is critical.

Clean Chemistry is focused on solving water treatment challenges with our cleaner, safer chemistry. Our mission is to develop and apply safe and effective oxidation solutions that align with today’s sustainability goals for use in energy, pulp and paper, food and beverage, cooling towers and any industry that relies on intensive water use. Contact Clean Chemistry today to find out how the many advantages of PeroxyMAX can improve your water treatment program.