Many industries use water as a main component of their operations. With a growing trend toward reuse and recycling, operators from industries as diverse as food processing, paper mills and oil and gas sites are looking at the economics of water treatment.

The industry has made much progress in understanding the required water treatment specifications for recycling and reducing treatment costs. A large part of these advancements lie in the chemistry of water treatment processes, notably the role of reactive oxygen species or ROS.

What Are ROS?

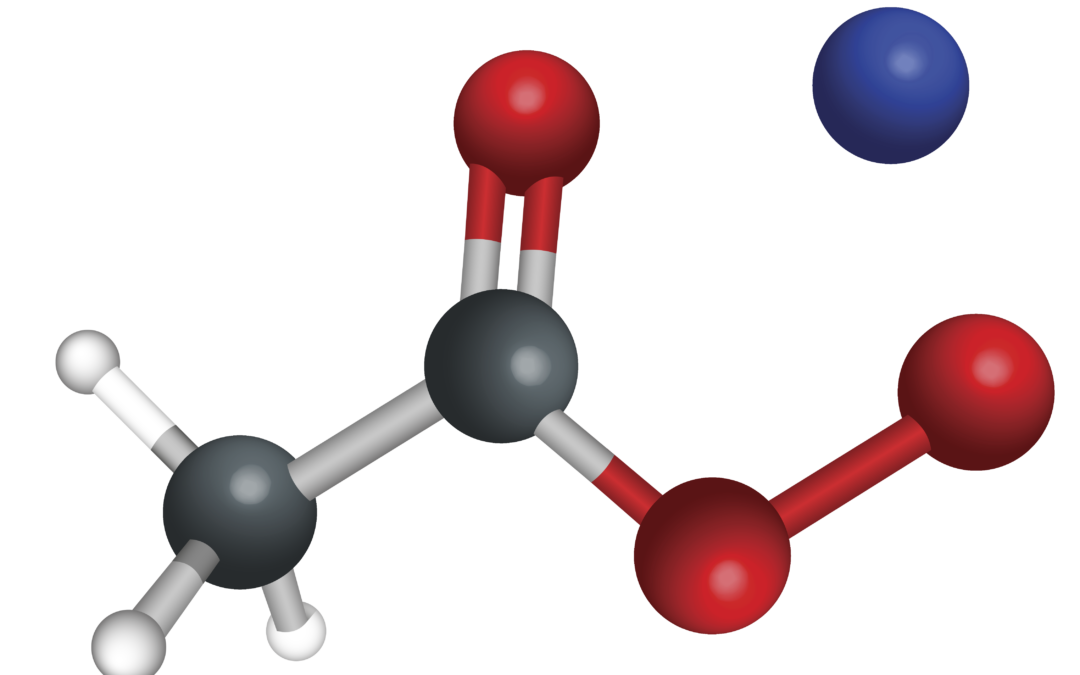

Reactive oxygen species (ROS) refers to multiple forms or energy states of oxygen with greater activity or reactivity than molecular oxygen, O2, present in air. Several ROS are naturally occurring in the environment, play critical roles in biological systems, and many have been harnessed for commercial uses.

Common examples of ROS include hydroxyl radical (HO•), hydroperoxyl radical (HOO•), superoxide radical anion (O2•-), excited-state singlet oxygen (1O2), and ozone (O3). In general, ROS in water are short-lived and, for commercial uses, are generated at the point of use or in situ.

How does this factor into water treatment? A paper published in Environmental Science Water Research & Technology states that reactive oxygen species (ROS) are highly efficient and versatile for the degradation of organic pollutants in wastewater treatment by advanced oxidation processes (AOPs). However, some ROS lose their efficiency as water becomes more impaired, especially with higher levels of salinity, anions and carbonates.

The most developed and successful AOPs produce ROS by catalytic, photochemical and electrochemical methods, which limit the applications to specific process designs or environments.

PeroxyMAX™: A Revolution in Clean Chemistry

Clean Chemistry, a technology-forward organization focused on solving the industry’s water treatment and microbial control issues with cleaner, safer chemistry has developed a safer, high-performance chemistry for water treatment: PeroxyMAXTM.

Employing proprietary chemistry, a sophisticated on-line sensor and automation package and digital dashboards, Clean Chemistry provides microbial control, water clarification, odor control and cleaner water for disposal. The process is accelerated and condensed for a smaller footprint and reliable and safe enough for unmanned operations with intelligent remote monitoring.

PeroxyMAX is an activated alkyl peroxide formulation in water that efficiently generates reactive oxygen species (ROS) by chemical activation without catalysts, light or electrodes at a rate that is practical to dispense as a liquid product. The ROS “supercharges” the oxidative activity of the parent peroxide. The primary ROS in PeroxyMAX is singlet oxygen, which is molecular oxygen (O2) in an excited state.

The combination of oxidizing species in PeroxyMAX provides enhanced performance while generating a significant oxidation-reduction potential signature which can be monitored and correlated to concentration or efficacy in a treatment process. This approach has simplified the use of ROS in water treatment by making it easy to incorporate into existing processes while focusing on non-radical oxidants (singlet oxygen, alkyl peroxides) that are chloride and sulfate-free and more compatible with salinity and other water treatment chemicals.

Advancing Safe Technology in Process Automation

Thanks to the relatively short half-life of the PeroxyMAX chemistry, it is generated on-site and on-demand in water from three stable, non-flammable liquid feedstocks in a safe, automated process. As a result, there is no storage required for the active product and no use of stabilizers toxic to the environment.

The product is produced and dispensed by a smart water treatment platform, which provides process automation and real-time quality control and monitoring in water treatment operations. These features equate to cost savings from greater compatibility, protection of capital assets, no chlorinated byproducts and improved operator safety.

The chemistry behind PeroxyMAX is an engineered and patented peroxide salt formulation in water, which delivers significant quantities of reactive oxygen species (ROS) that provide the horsepower behind its performance. The specific ROS, singlet oxygen and superoxide, in the PeroxyMAX formulation provide a strong and reliable oxidation-reduction potential (ORP) feedback for real-time process control. This ORP can be correlated with effective microbial control and therefore is used to control dosing.

PeroxyMAX does not produce halogenated disinfection byproducts in water treatment and residuals of the chemistry itself are generally regarded as safe (GRAS) and non-persistent in the environment. The PeroxyMAX system has a small footprint and low power requirements (single wall outlet). The chemical generation and water treatment processes are controlled and monitored in real-time and are remotely accessible by operators and customers through a networked dashboard interface.

Ideal for When Efficient Water Treatment is Critical

The selective reactivity of PeroxyMAX is also very beneficial for avoiding corrosion and degradation of equipment and materials. The inherent selectivity makes the chemistry less aggressive towards sensitive metals, polymers and elastomers.

As a result, PeroxyMAX has proven invaluable for any industry where efficient water treatment is critical. Examples of successful applications include farm irrigation systems, food processing plants, the bleach plant at a paper mill, fracturing operations on an oil or gas well or a water cooling tower are just some of the examples.

Clean Chemistry provides sustainable, customizable and smart solutions for difficult treatment challenges across a range of industries. Years of project experience and lab testing the selectivity of PeroxyMAX to target contaminants over other materials has been well established.

Clean Chemistry’s pioneering solutions, such as PeroxyMAX™, are just the beginning. Contact Clean Chemistry today to discover the chemistry behind the technology.